Dynamic Decarbonization and Improved Energy Efficiency using HeatX Novel Nanocomposite Surface Treatment

CHALLENGE

Fouling of heat exchanger (HX) equipment through the formation and attachment of hard scale, microbially-induced corrosion (MIC), or particulate erosion is a serious challenge to reliable production in the oil and gas industry. Fouled HX equipment performs 15-30% worse than rated abilities.

The Alaska Nikaitchuq upstream plant, owned and operated by Eni US since 2011, has experienced HX fouling and MIC situations since 2016. When an exchanger is unable to provide sufficient heat exchange due to tube fouling, a significant operating expense is incurred: Shutdowns equate to millions of dollars in lost production time and fouling inefficiencies and the need for supplemental heating is a significant source of carbon emissions.

SOLUTION

A comparative application was undertaken by Oceanit and Eni S.p.A. to evaluate HeatX on crude pre-heat trains (PHTs) at the facility. HeatX was applied to a shell-and-tube produced-water exchanger (PWX), while an untreated sales-oil production exchanger (SOPX) served as a control unit.

HeatX was applied to the PWX unit and compared to the control for a period of approximately 12 months. The ultrathin HeatX nanocomposite preserved and improved heat transfer rates on the HX surface by arresting corrosion and changing the surface energy to repel debris and fouling.

IMPACT

- A 12-month Eni S.p.A. and Oceanit pilot program demonstrated a 97% reduction of fouling in a refinery HX unit with nanocomposite treatment HeatX. The pilot compared a HeatX-treated unit with an untreated control unit.

- HeatX showed that treated surfaces showed a corrosion rate over 36-times lower when compared to untreated surfaces, while also completely arresting the formation of corrosion pitting, tube fouling, and erosion of the tube interior.

- Eni data showed that if applied facility-wide, savings in supplemental heating emissions would reducing carbon emissions by up to 17,000 tons annually in the pilot facility alone

- Taken on a global scale, HeatX’s ability to prevent fouling in power plant and refinery HX equipment could mitigate of 85 million tons of CO2 emissions annually

Get in touch

Learn how HeatX technology can improve your heat exchanger performance, drive cost savings, and reach your decarbonization goals.

A multi-stage deployment effort was undertaken by Oceanit and Eni S.p.A. to evaluate HeatX at four key stages and determine the economic and environmental value for Eni. These stages included: (1) Laboratory validation of HeatX MIC protection, (2) Fluid compatibility testing and pilot scale application with produced water spools, (3) Deployment and evaluation on representative shell-and-tube exchanger, and (4) Economic modeling of decarbonization effects on representative facility.

In this case study, we will focus on items 3 and 4 of the HeatX pilot deployment.

Fouling of heat exchanger (HX) equipment through the formation and attachment of hard scale, microbially-induced corrosion (MIC) products, or particulate erosion has been present at Eni’s Alaska Nikaitchuq upstream plant since 2016. Exchanger performance was degrading by 15-30% below rated abilities, requiring annual intervention to clean away biofilms and debris and the regular plugging of tubes to prevent leaks. These actions represent a significant operating expense in maintenance cost and lost production during HX downtime.

The extreme impact of fouling within HX systems is well-documented and correlates with loss of performance efficiency of operations. In a refinery setting, crude pre-heat trains (PHTs) function as inlet heating systems to heat production fluid as it makes its way to distillation, thus requiring less energy to reach distillation temperatures. Trains consist of various shell and tube HX units transferring energy content from back-end processes that contain heat energy, such as produced water and sales oil, to incoming fluids such as crude.

Typical inlet temperature averages approximately 55°F (12.5°C) and outlet temperature exiting the PHT corresponds to approximately 482°F (250°C) (Fraser, 2014); this increase in temperature results in the deposition of chemical and physical fouling formation which can reduce heat transfer efficiency for anywhere between 16-30% (Nakao, 2017, Costa, 2011). The key concept regarding PHT and all exchange systems across all industries fundamentally lies within efficiency of transfer. The more heat transferred in the PHTs, the less fuel will be needed to provide supplemental or “make-up” heating after it leaves the PHT, resulting in lowered greenhouse emissions and cost savings.

HeatX was applied to a HX unit, referred to here as the produced-water exchanger (PWX), while an untreated sales-oil production exchanger (SOPX) was used as a control. It is noteworthy that while both exchangers were contained within the same process train, the HeatX-treated PWX exchanger was exposed to crude, while the SOPX is exposed to oil that has already gone through separation and has had most of the water cut, sand, and excess gas already removed prior to export. As such, one would expect the PWX to show significantly more signs of fouling even if they had undergone the same length of service.

The units were left in service for approximately one year of continuous service, and prior to assessing the appearance of the tube sheets and tube ends both exchangers were pressure washed with hot water to remove residual product. No further cleaning was undertaken.

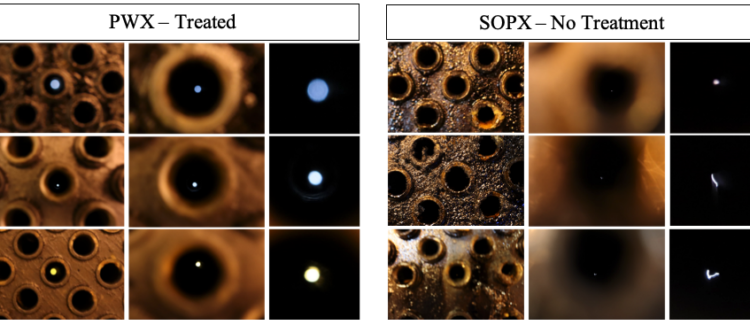

Borescope inspection was undertaken on the treated and control exchangers. The HeatX-treated PWX tubes, were clean and free of hard crude build up, with the grey metal finish of the tubes clearly visible on in almost all of the tubes. In contrast, the control SOPX tubes were entirely covered in black hard deposits from the crude, and early onset of pitting due to erosion and MIC was evident. Individual tube observation, conducted by shining light from one end of the tube, showed that SOPX tubes were consistently fouled and obstructed. Overall, the SOPX bundle showed notable amounts of hard deposits and fouling on both the tube sheet and inside tubes.

The following conclusions were drawn from this one-year pilot:

- No buildup of hard deposits from product fluid on HeatX-treated surfaces. Comparable SOPX unit had hard product build up and significant tube obstruction under similar operating conditions.

- HeatX material survived extreme E&P Flow entering Train 1 PWX unit (note that before application this unit was already 10 years old but held in storage) after 1 year of service.

- Treated surfaces were deemed acceptable for continued service in PWX unit. In follow up vacuum test, all HeatX-treated tubes passed test.

- Savings associated to annual corrective maintenance equaled to around 15% of annual maintenance operation costs.

After one year of service, Untreated SOPX unit vs. HeatX-treated PWX unit

Beyond prevention of fouling, an analysis of HeatX’s preservation of heat transfer efficiency was calculated. Fouling on tubular surfaces causes significant insulation on the tube, impacting the heat transfer. Additional heat input is required to reach the optimal input temperature in the control PHT, meaning more fuel must be burned to compel optimal separation and distillation processes.

By preventing fouling and preserving optimum heat transfer, HeatX pilot data shows that a complete removal of fouling would reduce annual emissions by 17,514 tons of CO2 annually at the Alaska Nikaitchuq upstream plant. To put this in perspective, this would amount to the same carbon sequestration of 19,500 acres of forest annually or 17.5 million pounds of coal burned.

Oceanit and Eni S.p.A.’s pilot test of field-applied HeatX demonstrated high effectiveness against corrosion by MIC, scale adhesion, and erosion. After exposure to real-world environments, the treatment showed both durability and compatibility with produced water and sales oil products, and greatly curtailed the effects of site MIC. By eliminating the effect of fouling within exchangers, the need for supplemental heating to maintain the design temperatures of the facility could be all but eliminated, providing annual emissions savings of over 17,000 tons of CO2 from the target facility alone. With the technology already having been substantially derisked in an extreme environment, and the immediate benefit of avoiding corrective and preventative maintenance costs has already been realized, it is expected that an extended deployment of the system will occur in the near future based on facility schedule and availability.

Images of tube blockages because of scale adhesion