Advanced Analytics for Industrial Thermal Systems

We Specialize in Advanced Algorithms for Thermal Systems

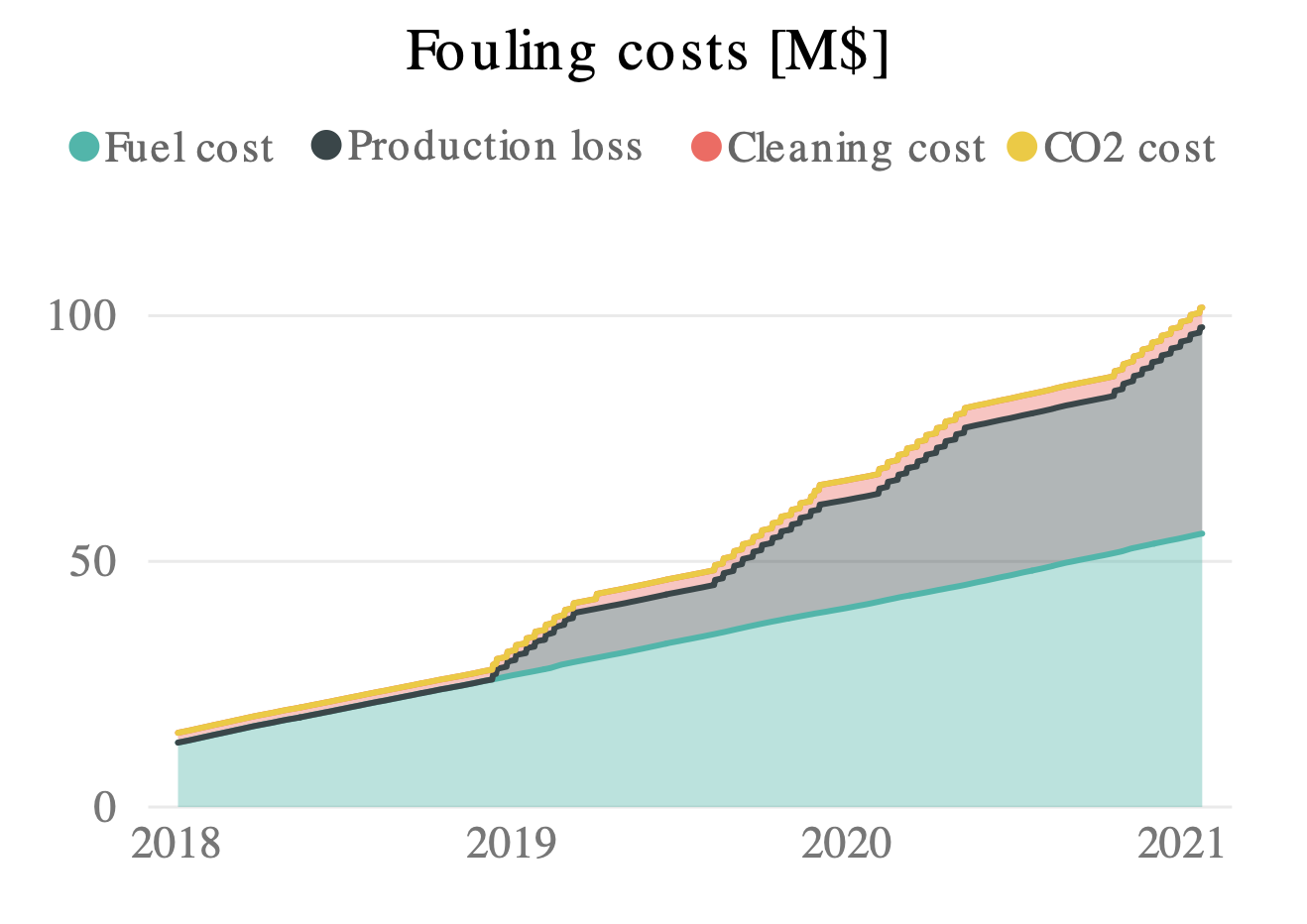

Over the years, Oceanit has developed specialized algorithms to analyze process data of thermal systems. ThermAI Dynamic Data Analysis™ and Fouling Propensity Analysis™ provide unprecedented insights and actionable information to improve long-term energy efficiency, reduce downtime and decarbonize thermal processes.

Dynamic Data Analysis™

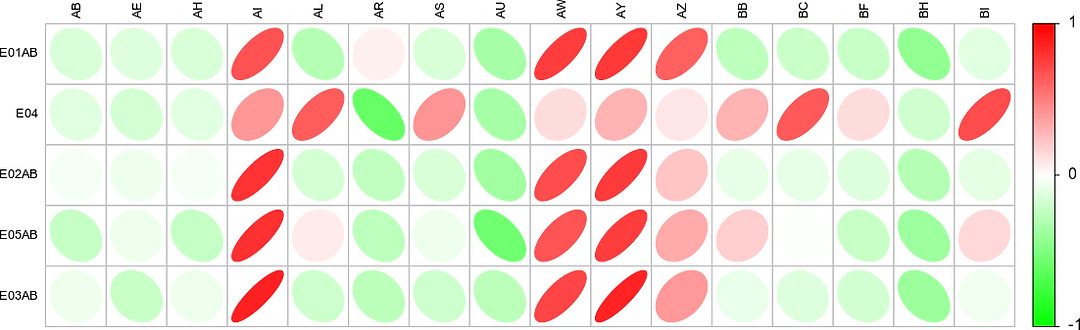

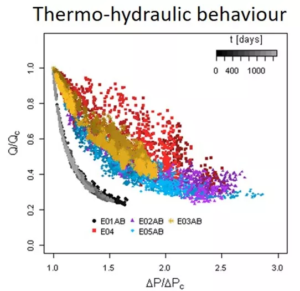

ThermAI Dynamic Data Analysis™ is a detailed analysis, powered by ThermAI Data Studio™, that uses historical plant data to provide deeper insight into the thermo-hydraulic and fouling behavior of heat exchangers than previously possible. Dynamic Data Analysis™ allows unveiling key correlations between operating parameters, crude slates and fouling behavior.

Key Benefits

1. Assessment of:

- Measurement quality

- Thermo-hydraulic performance

- Economic impact of fouling

- Efficiency of cleaning

2. Identification of:

- Key HEXs for performance improvement

- Opportunities for improvement

- Diagnostics of fouling causes and detection of changes in behaviour (e.g. inorganic breakthrough)

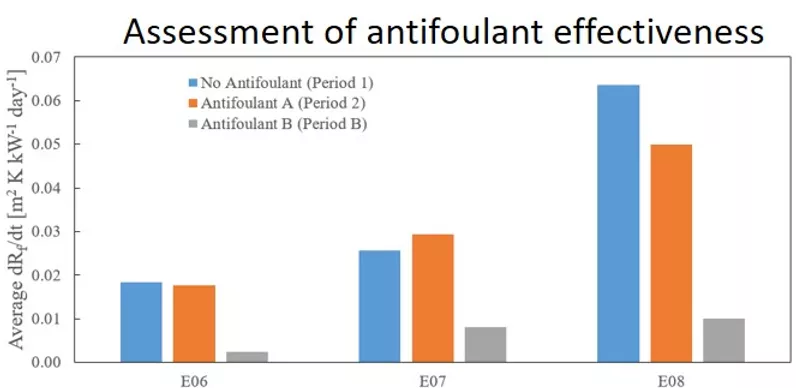

3. Impact of operations on fouling rates:

- Anti-foulants

- Bypasses

- Flow splits

- Revamps

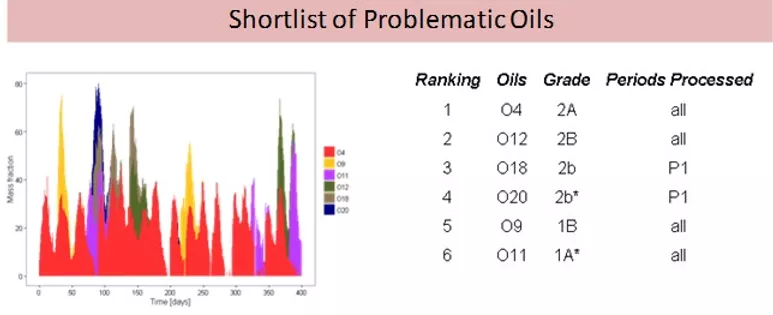

Fouling Propensity Analysis™

ThermAI Fouling Propensity Analysis™ uses advanced data analytics to provide a detailed analysis of the correlation between oils processed, fouling rates and operating conditions.

Key Benefits:

1. Identification of:

- Correlation between fouling rates, oil/blend physical properties and basic chemistry

- Problematic oils (i.e. related to high fouling rates)

- Beneficial oils (i.e. related to negative fouling rates)

2. Diagnosis of past acute fouling episodes:

- Oil slate vs. conditions

- HEXs in which oils are problematic

- Operating conditions at which oils are problematic

3. Recommendations on:

- Development of blending guidelines with plant data

- Future processing

- Further lab-testing