A Comprehensive Guide on Shell and Tube Heat Exchangers: Design, Functionality, and Applications

Introduction

Shell and Tube Heat Exchangers are commonly used in many industries, from power plants to petroleum refineries. They provide a robust solution for high-pressure and high-temperature applications, making them a crucial part of many industrial processes. Understanding their design, functionality, and applications can help optimize operations and achieve efficiency in heat transfer processes.

Design of Shell and Tube Heat Exchangers

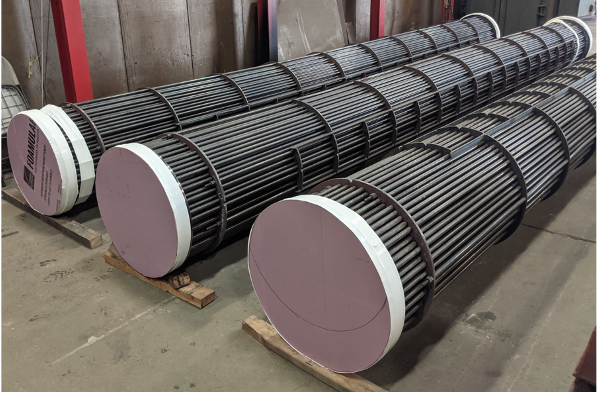

A shell and tube heat exchanger consists of a shell (a large pressure vessel) with a bundle of tubes inside it. One fluid runs through the tubes and the second runs over the tubes (through the shell) to transfer heat between the two fluids. The set of tubes is called a ‘tube bundle,’ and can be made up of several types of tubes: plain, longitudinally finned, etc.

Shell and tube heat exchangers are typically classified by the number of shell and tube passes involved. The design involves various considerations like material selection, corrosion allowance, tube thickness, tube layout, baffle selection, etc. Understanding these elements in detail can help in choosing the right shell and tube heat exchanger for specific industrial applications.

Functionality of Shell and Tube Heat Exchangers

The operation of a shell and tube heat exchanger is based on the principle of two fluid streams, with different temperatures, flowing close to each other in separate channels, and exchanging heat without mixing with each other.

The fluid that transfers heat is known as the hot fluid, while the fluid that absorbs heat is known as the cold fluid. In many applications, the shell and tube heat exchanger can be designed to recover and utilize the heat, improving the overall efficiency of the process.

Applications of Shell and Tube Heat Exchangers

Shell and tube heat exchangers are used extensively in many industries, primarily due to their flexibility, durability, and ability to withstand high temperatures and pressures.

In the power generation sector, they’re used in steam generators for power plants, waste heat recovery, and cooling hydraulic fluid and oil in engines. In the oil and gas industry, they’re used in crude oil distillation, natural gas processing, and condensing steam. Chemical industries utilize them for heating or cooling certain chemicals. They’re also used in the food and beverage industry to cool or heat large amounts of food products.

Maintenance and Troubleshooting of Shell and Tube Heat Exchangers

Regular maintenance of a shell and tube heat exchanger is essential to ensure efficient operation and to avoid the onset of ‘fouling’ – the unwanted accumulation of material on heat transfer surfaces. Various techniques can be employed to clean the tubes, including brushing, chemical cleaning, and high-pressure water jetting.

If a shell and tube heat exchanger is not performing as expected, the issue could be due to various reasons like fouling, tube vibration, leakage, thermal expansion, etc. Troubleshooting these issues involves understanding the symptoms, identifying the cause, and rectifying the problem.

Conclusion

Shell and tube heat exchangers are an integral part of many industrial processes. Their ability to withstand high pressures and temperatures makes them ideal for numerous applications. However, their efficiency heavily depends on proper design, regular maintenance, and effective troubleshooting.

As we move towards an increasingly energy-conscious world, understanding and optimizing the use of such heat exchangers will play a crucial role in enhancing energy efficiency and reducing CO2 emissions.

This comprehensive guide aims to provide a foundation for understanding shell and tube heat exchangers, but it is always advisable to consult with a professional or a trusted vendor when making specific decisions regarding your heat transfer needs.

To learn more about the right antifouling technology for your heat exchangers, feel free to contact our experts.