The global energy transition is perhaps the biggest challenge of our era, but Oceanit is actively working on developing technologies to decarbonize current energy production methods. These technologies give us the time needed to forge a path to sustainable and renewable energies.

Currently browsing: Tech

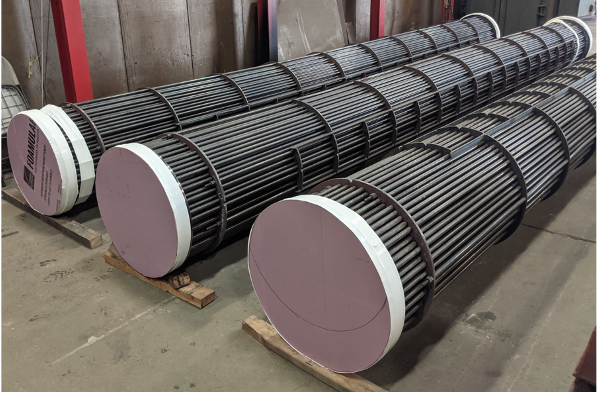

A Comprehensive Guide on Shell and Tube Heat Exchangers: Design, Functionality, and Applications

Regular maintenance of a shell and tube heat exchanger is essential to ensure efficient operation and to avoid the onset of ‘fouling’ – the unwanted accumulation of material on heat transfer surfaces.

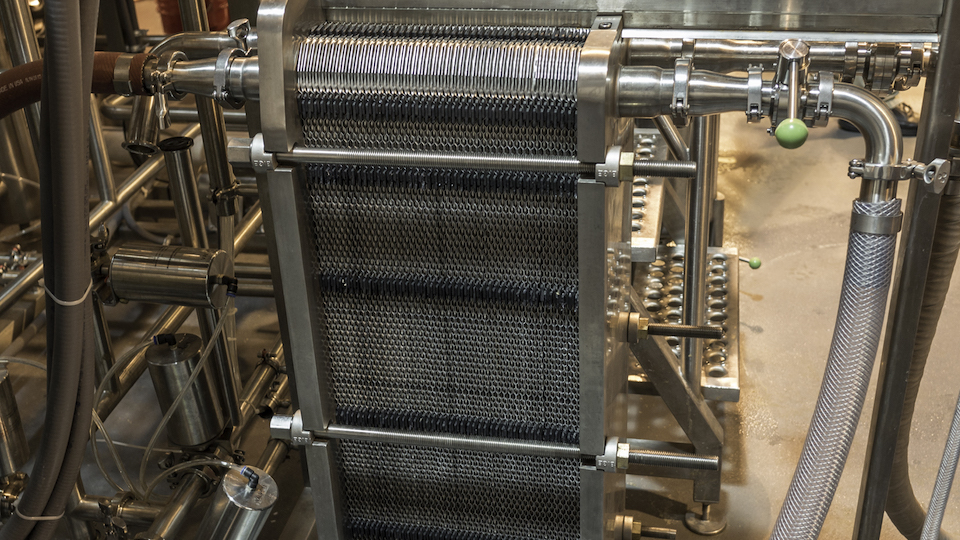

The Comprehensive Guide to Choosing the Right Antifouling Coating for Your Heat Exchanger

Efficiency of a heat exchanger is often compromised by a universal issue: fouling. This accumulation of unwanted material can drastically reduce the heat transfer rate, increase pressure drop, and lead to equipment failure if left unchecked.

How Antifouling Coatings Improve Heat Exchanger Efficiency

Introduction Heat exchangers are a cornerstone of many industrial processes, playing an integral role in energy transfer in various applications. However, they can fall prey to the […]

Materials Performance Magazine | Preventing Corrosion in Seawater-Fed Heat Exchangers

Oceanit’s HeatX nanocomposite surface treatment for dynamic decarbonization was featured in the September 2021 issue of Materials Performance magazine, in an article written by Rebecca A. Bickham. […]

Recent Posts

- Decarbonizing Coal to Secure a Sustainable Energy Future

- A Comprehensive Guide on Shell and Tube Heat Exchangers: Design, Functionality, and Applications

- The Comprehensive Guide to Choosing the Right Antifouling Coating for Your Heat Exchanger

- Estimating CO2 Emissions from Global Refineries Due to Heat Exchanger Fouling: A Comprehensive Analysis

- Estimating the Global Cost of Heat Exchanger Fouling: A Comprehensive Review

Recent Comments